ITEC engineering designs, integrates and supplies Integrated Control & Safety Systems (ICSS) for Oil & Gas Upstream production plants. Systems are designed to State of the Art standards with complete redundancy at Controller, Power Supply , Communication and Visualization levels .

Introduction

On a upstream Oil & Gas production site, all the daily activities are being carefully monitored and controlled to guarantee smooth production and to ensure environmental and personnel safety.

At the heart of the Central Control Room is the Integrated Control and Safety System (ICSS), which quietly regulates the production process by means of the Process Control System (PCS), Safety Instrumented System (SIS), Fire and Gas detection System (FGS) and Electrical Control System(ECS).

Real Time Information & Control

Within the control room, an overview of the production process is made available using ergonomically-designed Operator Control stations.

Any disruption to the process can be closely monitored in the form of visual, alarm logs and historical archives.

Operators are given real-time information necessary to make proper corrective actions to put the process back to track.

Should any unwarranted process upset occur despite operator invention, the affected process units will be shutdown automatically by the highly integrated SIS.

The SIS prevents escalation of process upsets due to equipment failure, sudden fluctuation in process parameters or human error, whilst manipulating the control features.

The smooth operation of the Plant is largely dependent on the effectiveness of the control strategies implemented by the PCS.

These include managing the start-up permissive, start-up bypass, sequence control, proper tuning of PID control loops, proper interlocking and recording functions such as sequence of events, historical archiving and alarm management.

In the emergency condition of hydrocarbon gas leakage, smoke or even fire outbreak, the Fire and Gas system (FGS) will detect any surge occurrence and execute protective actions. These include fire alarm sounding, fire beacons, fire or gas area indication and cascading signals to the SIS to protect process equipment by shutting down the affected units.

Key Benefits

> Seamless integration of PCS, SIS, FGS and ECS;

> Operator-friendly Human Machine Interface;

> Dedicated software library;

> Real-time data acquisition and display;

> Functionally separated safety systems approved by TUV up to SIL3;

> Optimized Performance to Cost of Ownership;

> Fit for Purpose design

Emergency Shutdown Hierarchy

Depending on individual plant practices, there are typically 4 levels of Emergency Shutdown Hierarchy.

Integration is tantamount to the ICSS where the status of all subsystems is readily available real-time at the operator's finger tips.

This is achieved through high speed Ethernet links between different sub-systems and seamless interfacing protocol that transmits data from controllers to Operator Stations.

Energy Management

Electrical Control System (ECS) senses, displays, records, trends, and alarms on information like energy flow, system topology, and equipment status.

It provides the operator and engineers with a centralized view of the entire facility’s power distribution system.

The electrical network can be operated from a central control room or from local control panel in a seamless manner for the operator.

Our standard libraries allow us to represent the electrical network in the form of animated single line diagrams, from an overall network level and down to details for each electrical substation.

This allows quick access to the status / control of:

> HV circuit breakers

> Main LV circuit breakers

> Turbine or gas engine generators

> Homopolar generator contactors

> Transformers

> Emergency diesel generator(s)

> Other equipment, such as UPS, HVAC panels

Emergency Load Shedding

Load Shedding functionality preserves system stability against failure or instability due to sudden overload following the loss of some of the normal operating generators, or the sudden application without warning of a large load. It quickly reduces the total plant load to keep key processes operating on the remaining capacity in the event of utility or generator loss. The system monitors designated field loads, power sources and builds a “load shed table” based on the steady state conditions, the instantaneous electrical system topology, and priority table designated by the user.

Our Electrical Control System continuously monitors the power system load balance and frequency and also calculates the maximum allowable power of the generators depending on ambient temperatures and other factors.

Two levels of load shedding are used. The first level, by detection of an under frequency consists of step by step shedding of HV breakers, according to the preset priority, which continues until the frequency returns to normal.

The second level of load shedding, by detection of a loss of an operating power source consist of a general shedding of load blocks. The amount of load to be shed depends on the power which was previously provided by the source which was lost and the capability of the remaining power sources. The load shed orders is applied individually to each HV circuit breaker.

Sequence of Event analysis

Tracing the root cause of a failure is often critical. Since we can support multiple event sources like protection relays or turbine control panels, we use our set of standard libraries, network protocols and dedicated time stamping modules to guaranty a fully synchronized System.

This allow us to show in a single SOE summary all significant events, alarms and actions which occur in the power generation and distribution systems, with a discrimination between events of 10 ms or less.

Sequence Of Event summary offers the possibility to select various presentations and filters:

> Event recording per geographical location

> Event recording per type of fault

> Event recording between specified dates.

Energy Optimization

ITEC engineering provides tools to monitor energy so you can make informed decisions on power use and costs.

Based on a web-enabled management software package, this gives you access to critical energy information from virtually any location. The software combines data collection, client-server applications, and Microsoft’s advanced .NET™ Web technology to provide you with a complete energy-management decision support tool.

You can capture, analyze, store, and share energy data with key stakeholders using a standard web browser. This makes it simple to distribute the knowledge necessary to optimize energy consumption, manage power quality, correlate energy usage, determine cost to production, and improve efficiency.

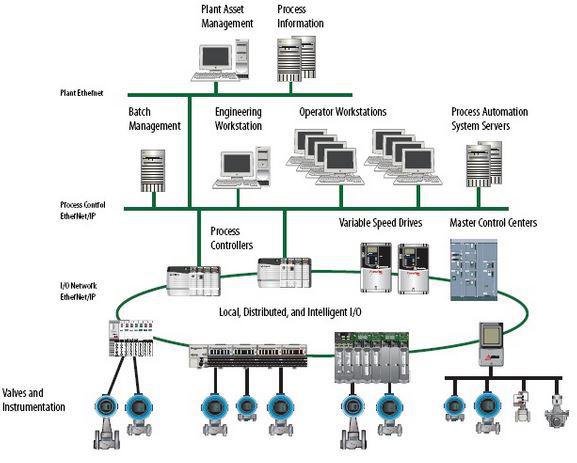

Technology

The PlantPAx® Process Automation System from Rockwell Automation is a modern distributed control system (DCS), built on a standards-based architecture by using Integrated Architecture™ components that enable multi-disciplined control and premier integration with the Rockwell Automation® intelligent motor control portfolio.

ITEC engineering has joined the Rockwell Automation Recognized System Integrator Program. Qualified members of the program represent system integrators that meet program criteria for operational excellence, application expertise and customer focus.

PlantPAx Benefits

The benefits of PlantPAx include but are not limited to:

> Operational and Cost Efficiency due to resource sharing such as Engineering Workstation (EWS), Automation Controllers, Operator Workstation (OWS), System Servers, Historian.

> Total Integration: Process and safety are totally integrated, allowing standard and safety programs to reside in the different part of same CPU.

> Customized Solution: Dedicated software library developed based on industrial standards and has a wide range of field proven function blocks to cater for requirement of our customers.

> Communication gateway is not required between the PCS and Safety System, thus eliminating another possible point of failure

> Common EWS (Engineering Workstation) for PCS, SIS, FGS and ECS

> Common hardware platform significantly reduces range of spares required

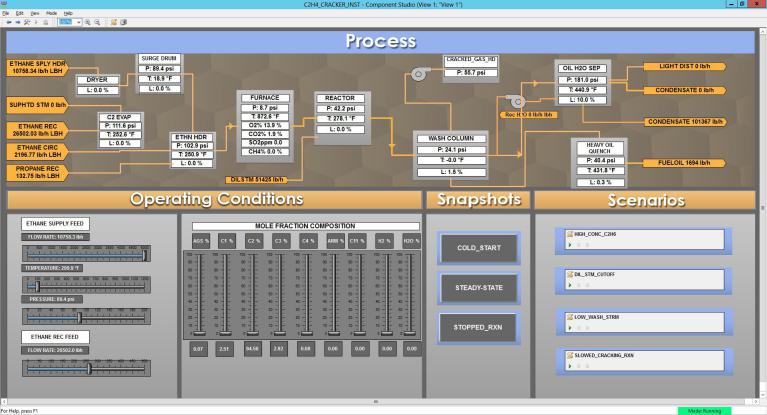

Operator Training on Virtual Plant

Highly automated plants require higher operator skills.

This is causing an increased demand for ongoing training for plant operators.

In addition, there is an extremely high percentage of operators approaching retirement age. Operation Managers are faced with is finding an effective and efficient way to conduct knowledge transfer from the experienced operators to the next generation of operators.

The better approach is investing in a virtual plant. The exact same operator graphics, alarms and controls used in the on-line control system are copied into a control system simulator made by ITEC engineering. The operator works on the exact replica of the system in the control room. A real-time, dynamic model of the IO and process is used to provide IO signals to the simulated control system. The operator and control system appear to be controlling the actual process. And, the entire solution is implemented in a virtual, private cloud environment.

By using the Virtual Plant, the user has an effective tool for reducing the risks in automating and operating the plant. These risks include:

> Hidden errors and issues in the automation system application software undetected until they cause process or operational issues.

> Inappropriate operator actions or conversely, operators not taking action when they should.

> Operating procedures that are in error or incomplete such that they are not used or trusted.

By testing the automation system and training operators with the virtual plant, the user can mitigate these risks and maximize the profitable operation of the plant.

Secured Remote Access

Our ICSS are designed with easy remote access and data services through LAN, Ethernet, WiFi, 3G, Satellite, etc

The flexibility allows a user to link remote ICSS in an environment where communication technologies are constantly changing.

Our solution uses an outbound connection across the factory LAN (HTTPS port 443 or UDP 1194). This makes the the ICSS access to be isolated from Internet by working with private IP address, non reachable from the Internet. No IT/firewall changes are needed to establish communication. A key asset that your IT team will appreciate!

We can use this solution as a data gateway allowing you to monitor and collect your data. Whether you need alarm management and notification, data logging and retrieval.